With data-driven support you see an immediate effect on support staff and customers

A large part of our customers are companies developing, manufacturing and selling their own machines. In addition to a good physical product, their customers expect fast and knowledgeable support. That’s where a data-driven support comes in. Customer satisfaction surveys show that customer support has a major impact on the overall customer experience of a product or service. Waiting times, competence, and response are important factors in how they perceive this. The feeling of being misunderstood or having to tell your case to several different people is at the top of reasons for irritation.

Machine manufacturers are no exception. The big difference is that their products require a high level of technical competence. Likewise, a production manager or operator at a customer’s site is also feeling a certain amount of stress when they call the support. Especially if the machine has problems or is standing still.

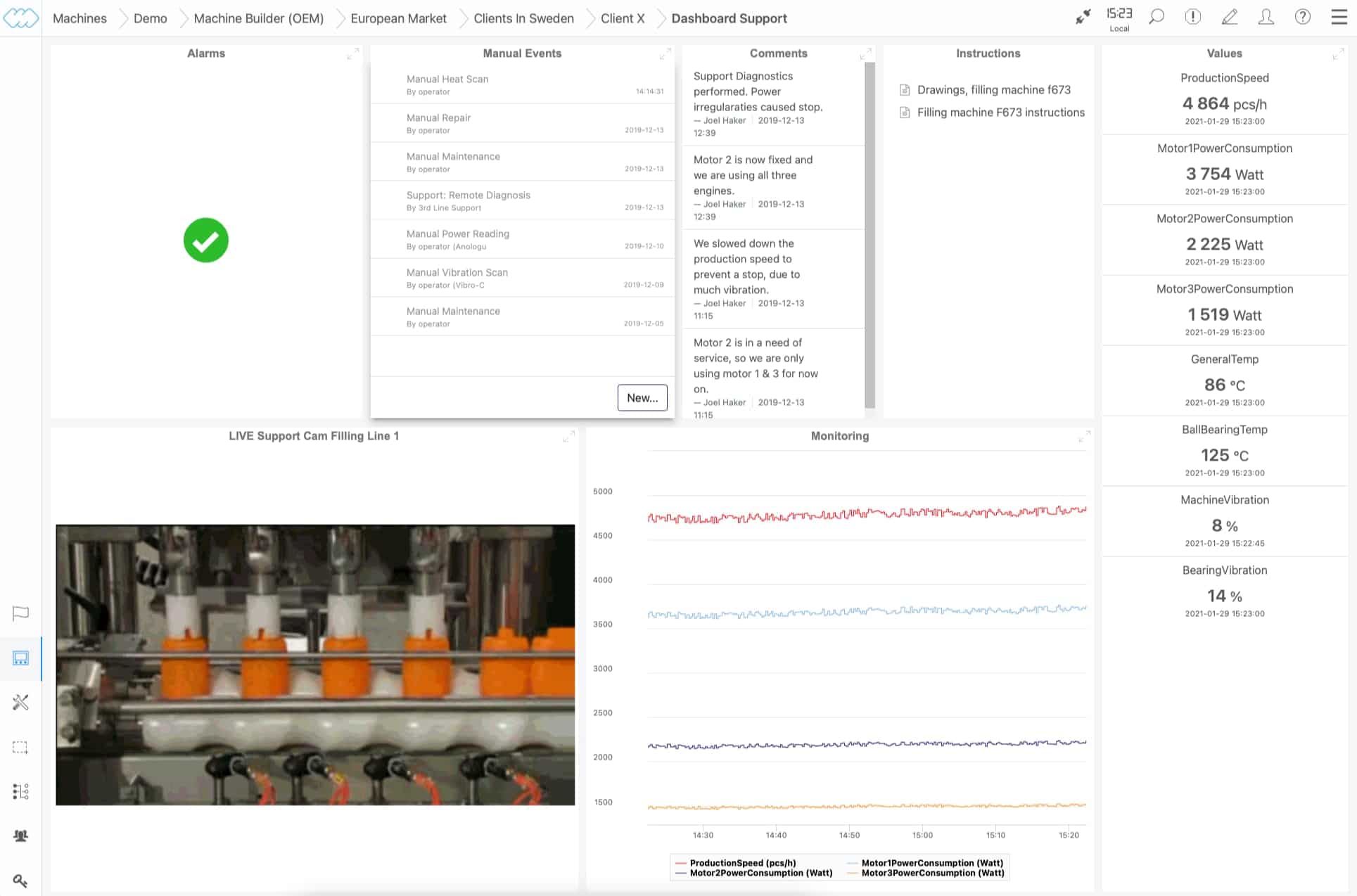

In a survey, many machine manufacturers, who use the portal in the Connectitude IIoT Platform™, answered that the data-driven support was one of the areas where clear and positive effects could be noted immediately. The relationship with the customers improved and their own staff isn’t as frustrated. In the autumn of 2020, we had got to study this firsthand through interviews with support staff from a few different customers. When asked which functions and tools in the portal had the greatest significance, we received fairly consistent answers and thus got a number of good tips to share with our customers. Here are some of the quotes from the support.

The diagnostic features

– The first thing that happened in a conversation earlier, was having to play detective without being completely sure that the clues you got were correct. Some customers were well prepared while others were a little more unaccustomed to explaining what had happened or how to troubleshoot the machine based on our instructions. It’s a tedious job, can take time and there is space for misunderstandings. Now we can directly see all the values of the machine in graphs and histograms. For an experienced technician, a glance at the machine’s “ECG curve” is enough to grasp what has happened and where the fault lies.

– Smart that you can match curves and history against other values and alarms.

– We have taught our customers to do certain types of troubleshooting themselves based on the values they receive in a customized version of the diagnostic tools.

– We have regularly started checking alarm lists and values for customers with many support tickets so we can warn them in advance if we see a risk, such as having run the machines too hard during certain shifts.

Chat feature in the data-driven support

– Even though we have a case management system in our support, we sometimes emailed answers to individuals at the customer’s end. With the chat inside the portal, you know that everyone responsible for a machine can read what has been said and done.

– Our work has been simplified because we can now ask the customer to take a picture and send it to us. It is difficult to measure the condition of a drive belt or bushing only based on sensor data. However, the quality of photos from today’s mobiles is enough to assess whether or not something needs to be replaced.

– The fact that the customer can use the chat to report less urgent matters has two advantages. They do not have to sit in a phone queue, and we are able to look at various machine data before we get in touch with the customer.

Document archive

– It feels safe to know that all instructions, service and maintenance reports, and other documents are available in a digital format and in one place. We don’t need to search mailboxes and binders. We also have customers where some of the machines have been around for a long time. In their machines, neither of the parts are originals which makes it extra important that everything is documented and easy to find.

– We save a lot of time by being able to update standard documents for all customers simultaneously. We also don’t have to email instructions and links to different people who work with the machine.

Built in logs

– It doesn’t happen often but sometimes it’s difficult to see or prove that settings for the machines have changed and by whom and how. Things like that are now in the logbook (Audit Trail feature). Our customers, or my colleagues, can also see the log. Instead of pointing a finger at someone, I can inform them of what can happen when certain settings or alarm levels change.

– If all customers do their maintenance as intended we can avoid certain types of stops completely. In Manual Events, someone at the customer’s end must confirm that they have performed the recommended service and inspection. Because of this clear responsibility and traceability, one can reduce the risk of negligence with the routines.

Easy to customize views and tools for the customer

– It is easy to give permissions in Connectitude’s portal and assign it to different roles at our customer’s. Then each role can see the tools and values most important for their tasks. Some of the more skilled operators may also have some unique permissions normally intended for maintenance and service personnel.

– The “ECG curve”, which I myself use for our own diagnostics, is something that customers like. Certain values such as speed, loads, temperatures in ball bearings, and power consumption are usually fun for people in production to be able to look at after their shift.

– We helped a customer to make reports where they can now see all important machine data such as curing times, curing temperature, and more per batch or work order. This led to them getting more assignments and needing another machine from us.

Don’t know where to start with a data-driven support?

No problem! This is often where we come in to help. The first step; contact us below!