In this article, we take a closer look at services around the machines, which for many machine manufacturers is one of the most important sources of income. You will receive tips on how a connected machine together with a digital data-driven service book simplifies your work and strengthens the relationship with your customers. This is the fourth article in our series about the life of innovative machine manufacturers and their aftermarket (links to the entire series can be found at the bottom).

To do as one has always done, but in the cloud, is not smart digitization

In 2010, all exhibitors at a teaching aid fair marketed that they had developed modern and fun digital teaching materials. The students and their minds would be even more stimulated. In reality, this meant that four out of five publishers now sold their old books as PDF files. Only one-fifth had taken advantage of the possibilities of the digital format such as animations, audio files, games, and self-correcting exercises.

In 2021, the range of digital service books give you a similar feeling. Paper, pen, and binder have certainly been replaced by mobiles, tablets, and the cloud when you fill in a maintenance protocol. For the rest, the routines for service have not changed much for a machine manufacturer and its customers.

Your machines have different needs of service and maintenance

Many years ago, a machine manufacturer who manufactures medium-sized buck cranes told us about a problem they experienced. Their traditional service level agreements with fixed intervals for inspection, fixed routines for customer maintenance, and a fixed price model per machine didn’t work. Neither for them nor their customers.

The wear on wires and motors was very different depending on how the cranes were used. When the machines were used with 90% of the permissible load, the wear on some parts was 4 times as great as at a load of 50%.

“Imagine if we knew exactly what happened to the machines at the customer’s end. Then their maintenance and our inspections could be made much smarter. And we could have brought the right parts with us for replacements even before the inspection”. The service manager’s words are just as wise today, and the technical possibilities have now caught up with his vision.

The connected machine is key to a data-driven service book

As mentioned in the previous article, different events and values in a connected machine can create different types of alarms. In the same way, different routines for service and maintenance can be linked to similar values and events. Something that will create opportunities for additional sales and strengthen the ties with the customer. Below we have selected service areas where a connected machine would help you both earn and save money.

Facilitate maintenance for the customer and relieve your service staff

A connected machine will be able to signal how often regular maintenance routines should be performed by your customer. You will also be able to trigger very specific routines for more unusual scenarios. If the buck crane in the example above had an unusually high load, the wires may have to be checked on the same day and not at the end of the month.

For those customers primarily having a service agreement as insurance, the daily interaction with a digital service book gives the feeling of the actual value. For those customers who previously thought that their service agreement cost more than how they use their machines, you can create more situation-adapted price models based on actual use and extended own maintenance responsibility.

Facilitate effective collaboration with local service partners

For long-distance customers, having a local partner with qualifications for certain types of service assignments can save time and money. Here, the handling and administration can be considerably facilitated. The amount of information that a user can see can be delimited in detail in a modern cloud solution. Therefore, it will be easy for the machine to trigger a dispatch of a completed work order and appropriate instructions directly to a local partner.

An external technician will only be able to fill in the parts of the service book that the case concerns. You will immediately receive a reliable digital signature when the case has been accepted, initiated, or carried out by the partner and everything that has been done is saved and traceable. Less time for handing over cases and less risk of sending the wrong instructions. Your customer avoids downtime costs and paying any travel surcharges for the service.

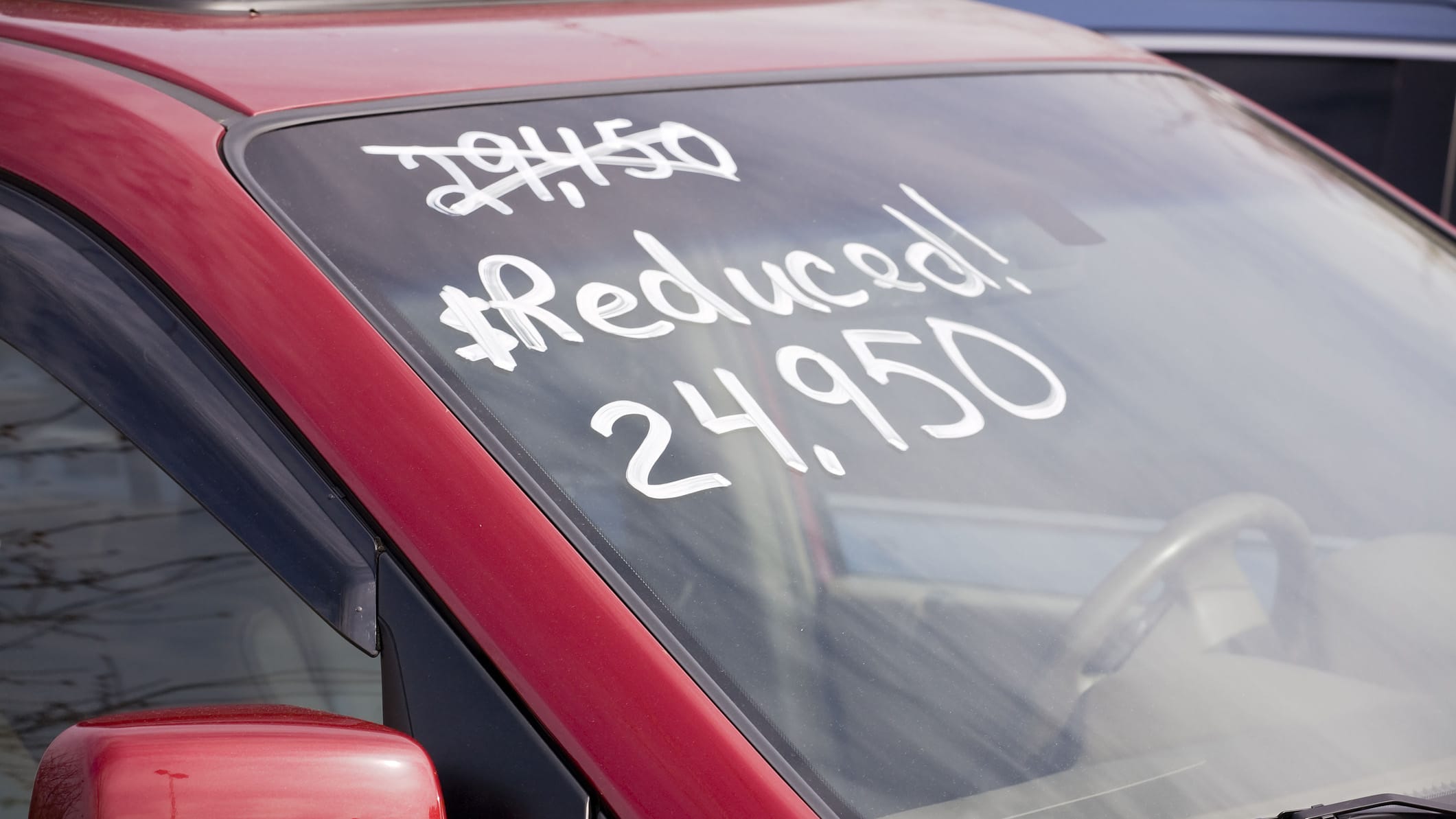

Create a secure secondary market for your machines

A service book is usually a very important part when selling a machine and the condition of it can affect the price. You will now be able to offer your customer a complete digital service book with full traceability to all alarms, measures, historical operating data, spare parts orders, invoices, and more. Complemented by the entire product history in the PLM / PIM system, you have made it much easier for the customer if they want to resell their machine in the future.

Sell new types of services with a data-driven service book

You will now be able to see your connected machines in one system, making it easier to make comparisons. On a larger scale you can see which machines perform worse in relation to a reference machine. You can also get an average value for customers with similar production. Also, all configurations in the control systems can be retrieved and compared so that incorrect or unusual settings are automatically identified.

In the same way that customers can have the OEE systems we described earlier, you can also offer the service yourself, extended with reliable key figures on how your customer relates to competitors. If you want to become your customer’s strategic advisor when it comes to production improvement, you now have the technical pre-requisites for it. The service book in the cloud can present measurements of different key figures with clear comparisons to last month.

Make sure that maintenance is carried out correctly and avoid unclear warranty matters

A normal digital service book can alert if no one has checked off the maintenance protocol at the appointed time. A service book for a connected machine can, for example, also react to someone checking that they have filled a tank, but the level meter hasn’t changed the same measured value. An alarm routine can then send an animated instruction to the operator. He will then know the correct way to fill the tank and the consequences of not doing so.

The machine’s sensor data synchronized with the service book and alarms significantly reduces the risk of negligence, cheating, and unclear warranty issues.

Integrating the data-driven service book with your business systems will show effect

Connecting the service book and your PLM / PIM system thus guarantees that instructions, pictures, spare part numbers, etc. are up to date. This reduces the risk of the customer or your service technician ordering the wrong parts or performing incorrect maintenance.

If you also integrate your ERP system, you will facilitate handling invoicing of services rendered. There are also benefits if the service book gets some information back. Traceability of orders, payments, and deliveries of spare parts via ERP provides a more complete picture of a service matter. It will also relieve your support department if the customer can see the status of an order.

The effect

Sometimes a data-driven service book have a feature where you can plan and optimize business for your service department. If the planning is in a separate system, the information in there can contribute with relevant detailed information about ongoing matters. The biggest benefit is still that you can aggregate data from all machines’ service books. And create good and long-term forecasts of where and when maintenance will be needed. On top of that, the service technicians’ journeys can be better coordinated. This leading to purchases of spare parts to be made with higher precision. Ultimately, this will lower your costs.

The information in the data-driven service book is also important for your sales staff. They can gain insight into the service situation and know where there may be business opportunities. In the next article, we will therefore present your brand-new seller. A salesperson who is at the customer site 24/7 and knows the exact needs of the customer. Because that’s what you get when your connected machine is communicating with the PLM / PIM system and your webshop. Learn more about how you can simplify every step. From the machine creating a purchase proposal all the way to you receiving a notification about the order. Stay tuned!

The series of articles about innovative machine manufacturers and their place in the aftermarket so far:

- The costs to avoid in your aftermarket

- Why the system support is deficient when it comes to the aftermarket

- IOT factory automation for increased aftermarket sales

- How your aftermarket benefits from a data-driven service book (this one)

- How to increase sales in your aftermarket with industrial iot services

- Oee and how to develop your features in the right order

- (Subscribe)