Most people know that machines and devices can communicate with other machines or with a human. Or vice versa. But is this internet of things? Or is it IIoT, Industrial IoT? Or neither?

The correct answer is: it depends.

Here we will explain the basics of industrial internet of things and to point out the most important differences in the comparison IoT vs IIoT.

Introduction to IoT in general

IoT stands for the Internet of Things. In short, it means the technology and facilitation for devices as machines and sensors to autonomously be able to communicate with other machines or humans via the Internet. Note that the device can operate on its own, within limits controlled by a set of triggers and rules defined by humans. For a machine to be able to define its own rules we also need to add Machine Learning or Artificial Intelligence.

If you feel a sudden craving for pizza, you can order a pizza via an app or a website. Payments are made online and you can get a text message from the supplier when the pizza is on its way. In this case, a human communicates with another human over the Internet, via connected devices, in Interfaces designed for humans.

If instead, your smart fridge knows the rule, that if it is empty at the 17:00 self-inventory, it must order a pizza over the internet, it is IoT. If your fridge communicates directly to a fully automated pizza baking robot, the communication furthermore can be made in a different format. A format optimized for machines. A short message with a binary or hexadecimal string can be enough for a large payload of data such as customer identification, preferred time for delivery, selected toppings, etc.

The Internet of Things is thus not a totally different or parallel infrastructure to the Internet of People, as we humans use in our daily lives for social activities, shopping, entertainment, and professional purposes. The technical differences lie foremost in the frameworks and standards used in communication.

When was the IoT invented

As soon as the first Internet and the World Wide Web was created in the late 1980s, machine data was also sent via the same infrastructure. Yet, the expression IoT was first coined by the Englishman Kevin Ashton in 1999. Together with the Massachusetts Institute of Technology, MIT, he was developing sensors with radio communication, assisting a process for inventorying lipsticks.

Realizing that their new standard for communication, RFID, would allow wireless data transfer at commercially attractive costs, he prophesied that all devices could and would be connected to the Internet in the future. In 2013 he stated ‘the future is now’. Technology in hardware, software, and the infrastructure of the Internet was good enough for his visions of IoT.

How big is the IoT?

The Cisco Annual Internet Report predicts that 15 billion unique machines and devices will be connected to the IoT in 2023. In 2018 the share was 33%. The other 50% in 2023 will be devices operated directly by us humans. Think of gaming consoles, mobile phones, and computers.

75% of all the 30 billion connected devices will be used by the consumer segment, often referred to as B2C, Business to Consumer. Hence 25% of the devices will be used by the B2B segment. Assuming that the 50% share of IoT devices is distributed evenly between B2C and B2B, a quick estimate forecasts 4 billion connected IoT devices for the B2B segment in 2023.

When it comes to the usage of bandwidth, the B2C non-IoT segment still wins hands down. According to Forbes, Netflix alone used 15% of all Internet traffic in 2018. However, high-resolution video streams for B2B IoT are definitely on the rise. Combined with Machine Learning or Artificial Intelligence, real-time video streams can be used in solutions for digitizing surveillance, analysis of production processes, proactive support, effective R&D.and more

Unique characteristics for Industrial IoT

‘Not all IoT solutions developed for the B2B segment are by definition IIoT-solutions. However, all IIoT solutions are by definition developed for the B2B segment’.

Aside from this philosophical logic, there are many differences between the requirements in solutions for general IoT and Industrial IoT, IIoT. The most important ones are listed below.

Requirements for hardware and infrastructure

The physical infrastructure and hardware for IIoT, have much tougher requirements since durability and reliability are absolutely imperative. The components must be designed for the variations in temperature, humidity, dust, vibrations, physical wear and tear, and other conditions in industrial environments. IIoT designed for specific purposes, such as maritime use, outdoor installations, or mounted on heavy utility vehicles used in mining operations, most often have additional hardware requirements.

Requirements for safety

The requirements in safety are different too, primarily regarding preventing unauthorized access to the control of connected devices and to their confidential data. Of course, it could be very annoying if a malicious hacker would get access to IoT devices in your home, like light bulbs and loudspeakers. Yet, the economic incentives to target critical B2B processes are higher and the consequences can be much direr.

Whether it was malicious or not to sabotage the Iranian program for enriching uranium, the Stuxnet Virus did raise awareness of the vulnerability of software for automation and industrial process control. To the defense of the Internet and IIoT, the sabotage was actually made on the premises of the production site. Automation engineers had unknowingly had their physical USB memory sticks contaminated. Read more about the elaborate operation here.

Requirements for IIoT data to comply with laws and regulations

Some industrial processes are regulated by laws and therefore require granular tracking of uncompromised data as sensor values, alarms and events. Not having structured and reliable data can lead to fines and other sanctions. For example, all commercial ships arriving in the waters and ports of the USA must be able to provide reports of all their emissions and the management of ballast water, upon request by the US Coastguard. Here is more reading on how these requirements are managed by an IIoT Solution.

Requirements to comply with Industry 4.0 and various industrial standards

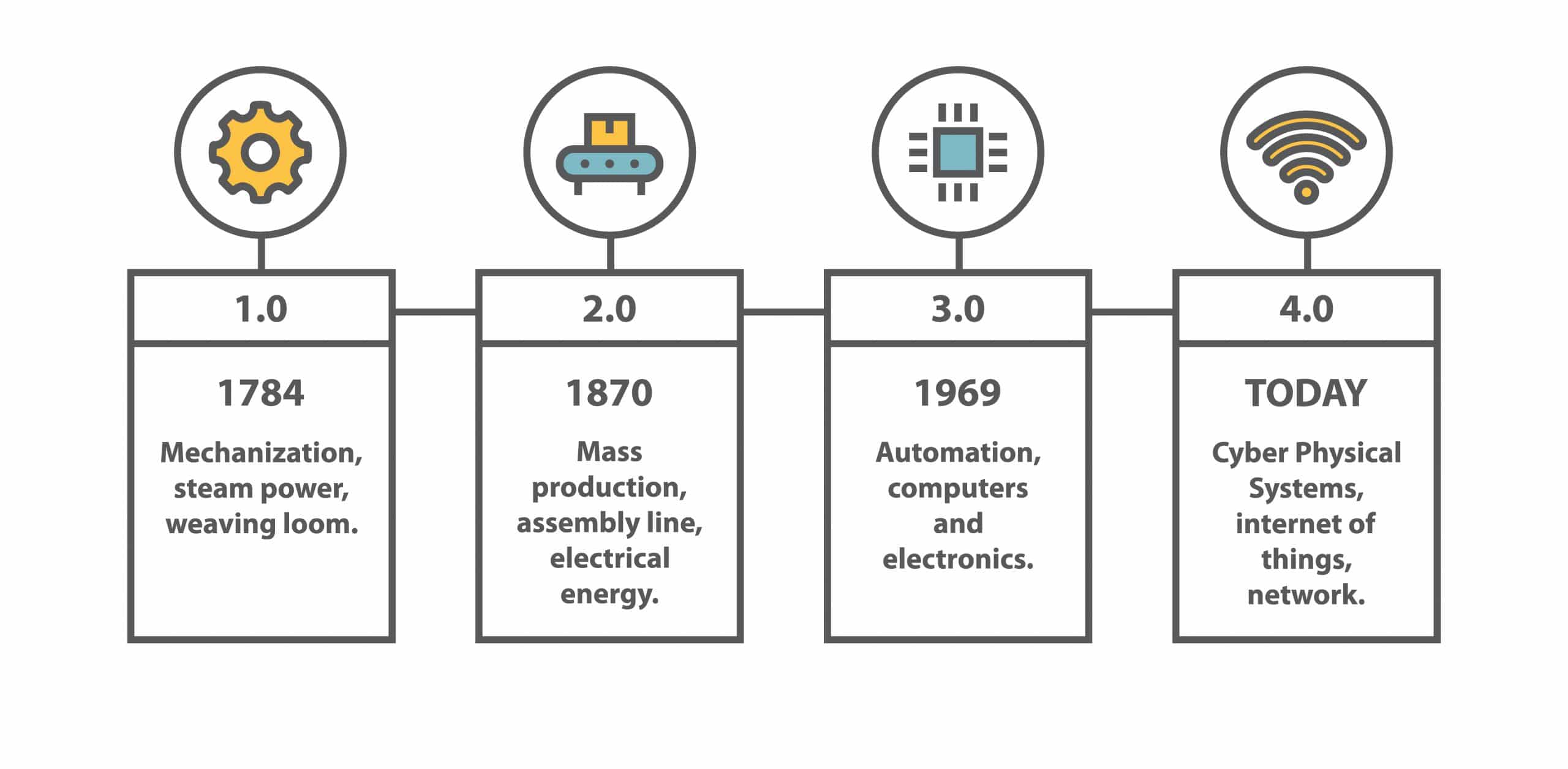

The fourth industrial revolution was more or less defined by the German government in 2011. In cooperation with companies like Bosch, Siemens, and Volkswagen the industry 4.0 paradigms were based on four principles.

- Interconnection

Machines, devices, sensors, and people must be able to communicate with each other via IoT and Internet of persons.

(In this perspective, there is no difference between general IoT and IIoT.) - Information transparency

Operators will be provided with comprehensive real-time information. Analysts and management will be provided with reliable, traceable data on a more holistic level, assisting identification of where improvements can be made in process steps or a complete production process. - Technical assistance

The system must be able to assist humans in decision-making and problem-solving and help humans with difficult or unsafe tasks. - Decentralized decisions

Components in a cyber-physical system should be able to make decisions on their own and to perform their tasks as autonomously as possible. Only when encountering exceptions, or conflicting goals, tasks will be delegated to more central system functionality or to humans.

Industrial protocols

To comply with the paradigms for Industry 4.0, machines must be able to communicate with other machines. However, different brands of machines and sensors talk in different languages, and some even in secret codes. These languages are called industrial protocols. It’s an advantage if your IIoT solution knows these languages, and add translation tools for less used protocols. A machine should also be able to talk to a non-IoT/IIoT software, for example, to tell an ERP-system to create a purchase order for spare parts or consumables. It is another advantage if your IIoT solution can talk to external software regardless if they are installed on-premises or as a cloud solution.

The biggest difference, IoT vs IIoT

In 15 minutes you can be up and running with a B2C IoT-solution in your home. The most well-known Swedish producer of furniture offers a package-deal including an IoT Gateway and some remote-controlled light bulbs. Just download the app; connect the gateway to your Wi-Fi; hold your light bulbs close to a gateway for a safe handshake; done.

Not that many IIoT-projects are decided on impulse and completed in 15 minutes. Even if it theoretically can be exactly as fast and easy.

The Connectitude IIoT Platform™

Our fastest implementation of an IIoT solution was made in 26 minutes. From arriving at the customer, machines were connected and dashboards for the operators were distributed. To be fully honest, that is a rarity. What often takes more time is choosing a solution. Some IIoT-solutions are designed to be “one size fits all”. They might require a specific brand of sensors and control units such as PLCs. Some platforms merely offer infrastructure without turnkey functionalities, and you have to design and develop any feature you need.

In the Connectitude IIoT Platform™, you will get the perfect sweet spot in between the extremes. You will get a multitude of powerful turnkey features that you can use from day one. When you are ready for customizations such as unique features and integrations, you will enjoy extensive and flexible possibilities. The intuitive design of features and extensive documentation will guide you on your way to successful projects. If you need more assistance, our support team and application specialist will help you.

And yes, the Connectitude IIoT-platform™ is IIoT, not only IoT. It is as IIoT as it gets.

Want to learn more how to future-proof your products with IIoT?

Seeing is believing. In a one-to-one live webinar, you can ask all the IIoT questions relevant for your business, free of charge.