.Many have learnt the hard way

Recently, we have been contacted by several procurement consultants specialized in Industrial IoT (Industrial Internet of Things). The existence of these kind of services is a good sign that the market matures. Compared to previous years, customers have a much clearer picture of what functions they expect from cloud solutions and SaaS (Software as a Service) platforms for industrial purposes. A large proportion of the questions we receive in RFIs and RFQs relate to technicalities, i.e. how storage, data traffic, calculations and validations are managed in the Connectitude Industrial IoT Platform™. This is due to a growing concern on what the monthly price tag will be for various scenarios and amounts of data processed.

All forms of storage, traffic and processing of Industrial IoT data as cloud services come with a cost and it can be hard to foresee the full cost in the early stages of an Industrial IoT project. This is confirmed by the many companies contacting us for help since their costs from cloud services have been significantly higher than in the initial calculations. Decreasing the number of signals and their sample frequencies will of course result in less costs, but the performance and response times etc. may suffer. Here are seven ways to cut costs without making sacrifices.

Our seven best tips on how to save money with Industrial IoT

1. Not all data has to go first class

The majority of all Industrial IoT solutions and SaaS platforms utilize services from a few large cloud providers. We are no exception. Microsoft, Amazon, IBM, PTC are some of the companies that offer a wide range of services for developing Industrial IoT platforms in their clouds. The alternatives for storage, filtering, analysis and digital gatekeeping for your data are plentiful. Beside great functionality, security and uptime are high, scaling of capacity for your needs is dynamic and swift. When you see price lists based on maybe 1000 signals or less it is easy to be tempted to send all data to services with the absolute best performance and greatest functional depth.

When doing a PoC (Proof of Concept) with one machine and a few selected signals, the differences between the alternatives can feel like coffee money. However, don’t forget to count on the complete scenario. The calculation is easy to do since the costs often scale linearly with the number of signals. Quantity discounts are not the focus of most cloud suppliers’ business models. Categorize your data in priority levels and select the optimal price performance ratio for each level.

2. Start at the edge

The level of your Industrial IoT infrastructure that collects data from your machines, sensors and more and sends them to the cloud is usually called the edge. The edge often means a device operating as field gateway. The smarter the software you have in the edge, the more options you will have to filter and manage your data locally, before it is sent to the cloud.

If a signal must be measured every second, it may not be necessary to forward this data to the cloud every second. In a smart gateway you can set various rules and dead bands for when data should be sent. For example when a parameter changes value or does so by more than 1%.

3. Send larger packages of data

In most cloud services, packages of data have to pass the IoT hub. It is a function that can most easily be described as the airport security or post terminal for your data. Here, each data package is checked so that it has been sent securely and that the content is in the correct format for future handling. Each package passing the IoT hub will have a transaction cost that is basically the same for small and large packages.

If your local gateway is smart, it can send your data in larger packages and more effectively. For example, it may choose to send packages of low priority data less frequently or only send packages when they have reached a certain size. Not so much different from modern logistics and transportation of physical goods.

4. Analyze and calculate your data before it reaches the cloud

The cloud providers usually have powerful features to manage routines and workflows that are based on conditions for various data. Firstly, data with images can be sorted out or analyzed. Secondly, alarm codes and events can start different workflows. Selected data can be directed to machine learning features, and so on. Again, cloud providers’ default services can be very good and worth the price, but it will nevertheless be lower costs if you can do more of operations and filtering on the local level. Moreover, features as alarms and process views can be more secure and fast if they use data as early in the information routes as possible.

A simple yet significant example where local calculation saves transaction costs

One of our customer’s production line sends its data 24/7. Each vital machine in the line sends a signal every second confirming if they are on or off. In an average day the machines are in off state three to ten times. The maintenance staff always get notifications when a machine is down. If you don’t have a smart edge, 86 400 signals per machine must be sent to the cloud and pay fees both to the IoT hub and to the alarm and event filters and the notification services. If you have a smart edge, you only need to send data to the cloud when status changes and your alarm log, in this case about ten times a day per machine

5. Optimize costs for data storage

At home, you can sort and store your things in various ways. You can put the fine porcelain in the kitchen’s display cabinet. However, it may not be an optimal solution for storing old sweaters and shoes. A large plastic bag in the basement with the text “miscellaneous clothing 2011-2015” written on a piece of masking tape, is maybe good enough. Not always quick and easy when you need to access a certain item, but the cost is low.

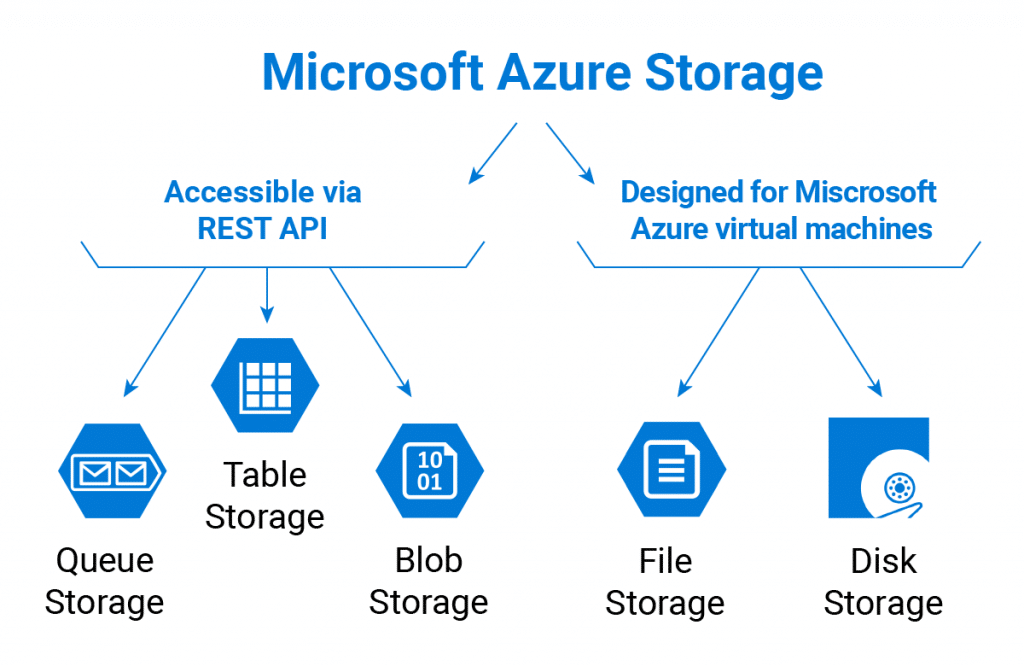

Roughly put, this analogy can be used for describing storage in the cloud. Data that is hot for the moment you might want analyzes without annoying delays, while it might be acceptable if it takes a couple of seconds to summarize various data for an annual report. Take advantage of the services most cloud provides automatic and timely migration of data between different storage options as time passes.

For storage alternatives that most resemble “the basement” in the analogy (e.g. Blob Storage, Data Lakes), we have put great efforts to increase performance. By creating virtual partitions and smarter indexation of data, the cheaper alternatives can be much faster regarding finding and retrieving data. You can search in all your plastic bags for the yellow sweater you stored in January 2013. You can also use smart algorithms to calculate the highest probability for where it ought to be stored.

Some of the options for storage provided by Microsoft Azure. For a more comprehensive list, Click Here

6. Exploit the virtues of TSDB, time series databases

Traditional SQL databases have their merits for storing data in tables and columns linked together by various relations. For IIoT purposes, timestamp and numerical values are the most central information. Time series databases, TSDBs, are optimized for this kind of data. In regard of performance a TSDB provides three major advantages compared to SQL databases:

1. Less data is needed to provide the same or better information meaning less bytes to store.

2. It is faster to write to and read from time series compared with clusters of tables.

3. Large and complex calculations of metric data is generally faster.

For more general data, a TSDB may not be the best option. That’s why we use a mix in the Connectitude Industrial IoT Platform™

7. Chose a fixed price for your Industrial IoT solution

If your cloud solution provider say they will forward the invoice from Microsoft, AWS, IBM etc. for services used for storage and services, with no additional charges it can sound almost as philanthropy. In your next thought, what are the supplier’s incentives and responsibilities to design solutions where cloud costs are in focus?

Most of our packages in the price list have fixed prices with a given amount of storage and traffic included. This has two reasons. The first one is to save our clients from the confusion cloud providers price lists can cause. The second one is that we have designed Connectitude Industrial IoT Platform™ to be very modest in its use of services with cloud costs, hence we can guarantee enough storage and transactions at a fixed price.

Conclusion

Architecture, the choice of cloud provider, packages sizes, storage options, settings and price models are just some of the factors affecting the costs of your cloud services. And some of the factors are constantly changing. It can be a complex task to optimize your cloud costs. Let us help you to cut the costs for cloud services. From general advices for free, to a full due diligence of your existing Industrial IoT-platform.

Contact us!