This si about industry automation and how to improve communication and teamwork between production shifts.

The daily matters are what matters

Those you meet in the industry will have an interest, and sometimes even demands from management, to optimize production through smart industry automation. True. Also, most people today have good insight into the possibilities of reducing the number of unplanned downtime through Machine Learning and advanced algorithms for Predictive Maintenance. True.

However, most probably your host already has a powerful old SCADA and DCS system that doesn’t have to, or can, be replaced urgently. Similarly, before investing in a new crystal ball, filled with Artificial Intelligence, will receive priority, there are needs that feel far more urgent to act upon, in everyday life.

There may be poor communication and mood between the shifts; uneven production rates; poor follow-up of stop and lead times; acute production problems; the reporting work after the shift; to name a few examples of what usually gnaws most in the management and middle management. Another frequent topic is how to get the staff more involved and taking more initiatives in production. Everyone is aware that better feedback loops are key to motivation and that the old fork binder for improvement proposals is not the optimal solution. Especially not when it occasionally is missing from its shelf.

3 new tools for communication

Distilling the inputs from the meetings, we saw three main areas where lack of data created most uncertainties and non-uniform processes. The staff was often uncertain that instructions were correct and updated, also if a problem they noticed already had been registered, or was in progress. We designed three features for better content management, communication, and tracking of actions, in the Connectitude IIoT Platform™.

- Instructions. A digital archive where all media related to a machine or process can be stored and updated with ease. Instructional films, maintenance protocols, service agreements can be accessed via a mobile phone or any PC. Alarms and notifications can be added to a file to prevent the renewal dates of contracts or revisions of instructions are missed.

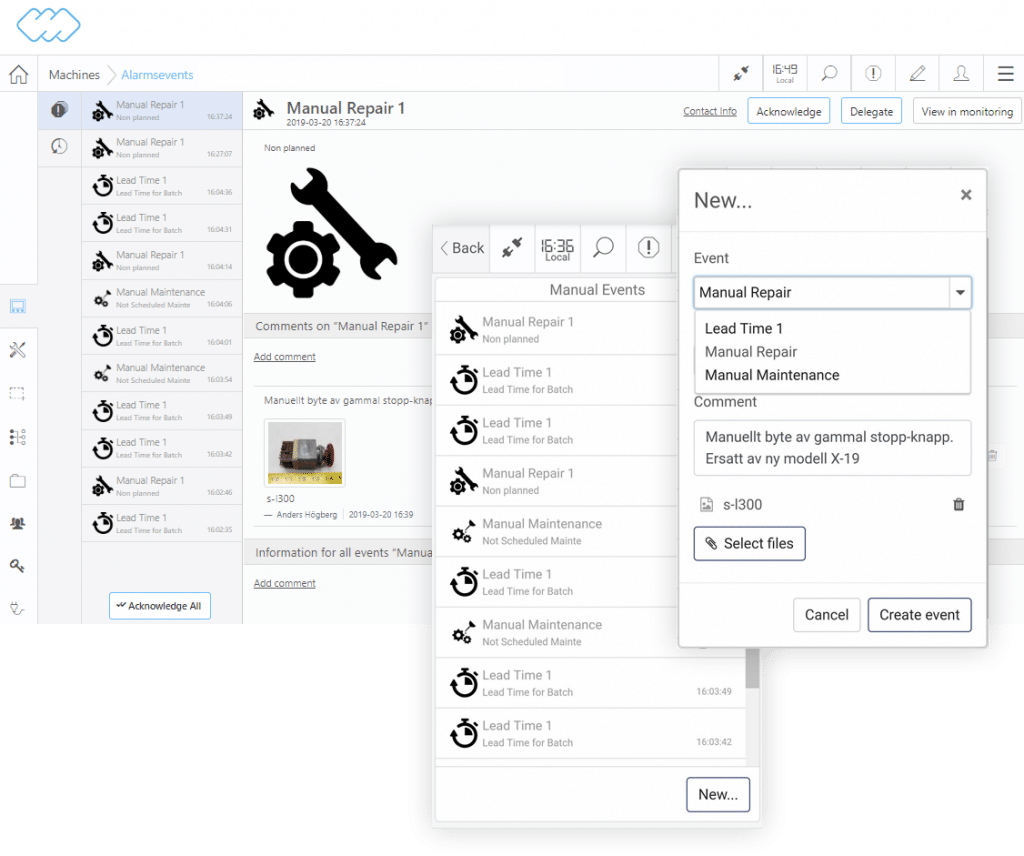

- Manual Events. This feature can be used to register any unplanned events as maintenance and repairs, as well as the start and stop time for any recurring process. Used on a mobile phone, creating an event is as fast as sending a text message. Event categories can also trigger workflows, distributing notifications and tasks to designated users. Good ideas for improvements and purchases can also be managed more effectively, with full transparency and instant feedback.

- Comments. A dedicated chat function for specific entities, as machines or processes. A more informal way of sharing daily information, and attachments as photos, between the shifts. Compared to the action log Manual Event, Comments is more the longterm diary. Suppliers can also be invited to join a conversation to make communication and troubleshooting easier.

It is ok to compete!

In one assignment, the client’s total production rate was satisfactory. However, the difference between the minimum and maximum values of the production rate during the day was extreme. The client wanted a more even production rate during their shifts and to equalize the differences in the rates between night shifts and day shifts. All relevant data was already registered in the management’s SCADA system and on an OPC server, but it was only shared with the staff as a monthly report.

Both workers and their unions welcomed a system where production rates were monitored and compared in real-time. This might be surprising, but it is not that different from why we count goals and measure performance in sport. It gives meaning and it shows the effects of our changes in methods. The Swedish company Insert Coin AB are specialists in creating gamification of industrial processes. Their studies conclude that moderate competition at work creates increased teamwork and leads to more initiatives for improvements. The important thing is to select relevant measurement results and present them in a context that everyone clearly understands and accepts. In this case, uneven production increases the risk of accidents and injuries.

Do you also want better teamwork?

Contact us for more information and solutions on industry automation, improving communication, routines, OEE, and teamwork in your production.