The Big Red Machine you see in the image is the hockey team most in tune with each other so far in world history and a perfect metaphor for perfectly synchronized processes and system support. Otherwise, we don’t feel the need to be associated with the former Soviet Union.

In our first blog piece about the life of innovative machine manufacturers in their aftermarket, we covered some of the challenges and risks of unnecessary costs that can stand in the way of a profitable aftermarket. Our point is that the machine itself should be the hub for how to build its information structure and its processes. Likewise, many different systems and add-on modules may be required to create efficient routines with good traceability at all stages of a machine’s product life cycle. We also described some of the most common systems and functions needed in an overall solution.

System support and the aftermarket and how they interact in reality

One of our customers is using most of these tools in his business for a long time. They have invested a lot in adapting the systems and their own processes. Despite this, there are still extra work, information loss, and direct errors in various parts of the delivery chain to the customer. The integration between different software has reduced manual labor of entering data, but they still don’t feel they have the overview they had hoped for. For the company’s various departments to be able to work better together in projects that require coordination, a joint case management system was implemented. The advantage of this it’s easy to mark a task finished via mobile phone. The disadvantage of planning, and documenting deviations is experienced as too complicated by many employees.

Overall there’s better control of the project and timeline but the transparency or cooperation between departments hasn’t been improved. Buying expensive business systems, however, doesn’t guarantee a perfect whole. The problem is just like when the music industry tries to put together superbands by bringing together several world-class musicians. They rarely work well together and there are too many egos to be dealt with. Everyone wants to be the star and play their own music. Let us explain this more in detail and how it applies to the everyday life of a machine manufacturer.

The process when the machine manufacturer’s customer wants a new conveyor belt

In this example, our customer sells and repair large machines that process wood. They have several standard products, and they also create completely unique solutions for the customer. One of their most important customers wanted that the conveyor belt itself to be able to steer different parts of wood for different machines and doing so by marking the wood. Continuous adaptations of machines and plants are an important part of their aftermarket. The solution for handling the ID marking became so good that it became a new standard product.

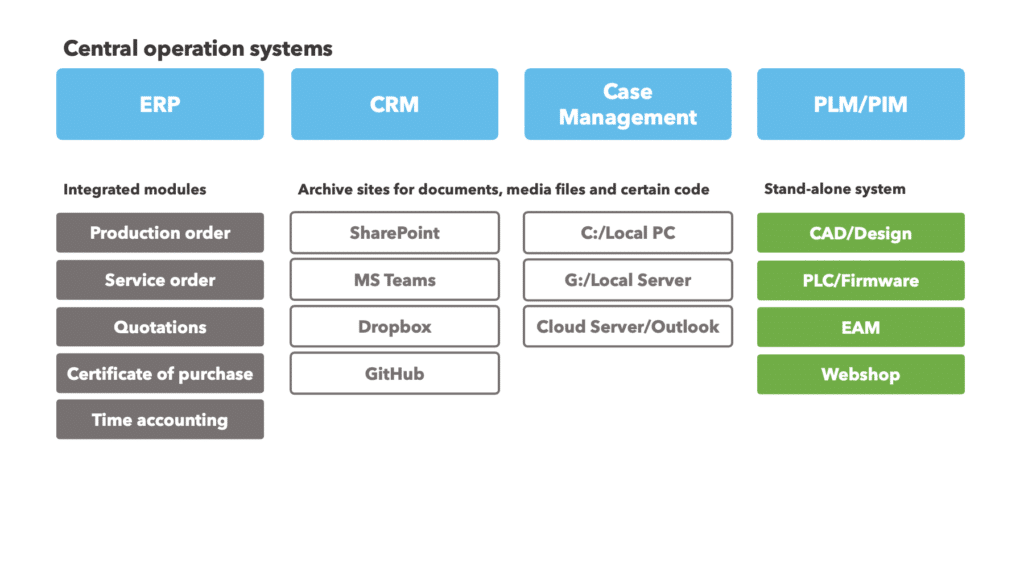

The design of the conveyor belt was created entirely according to the customer’s specifications and dimensions. In all stages from doing feasibility studies to installation and commissioning, many people and systems are involved. In addition, to develop and document the technique all major projects have a detailed description of costs of, for example, the purchase of parts and time spent. The picture below shows a somewhat simplified overview of the systems the customer uses to manage similar projects.

Reducing the number of different locations to store documents and other files is an important part of the machine manufacturer’s quality work making this just a matter of time. However, they must, for example, keep several old licenses for design and programming tools to be able to update different generations of automation solutions.

How the systems work together and what kind of system support is needed

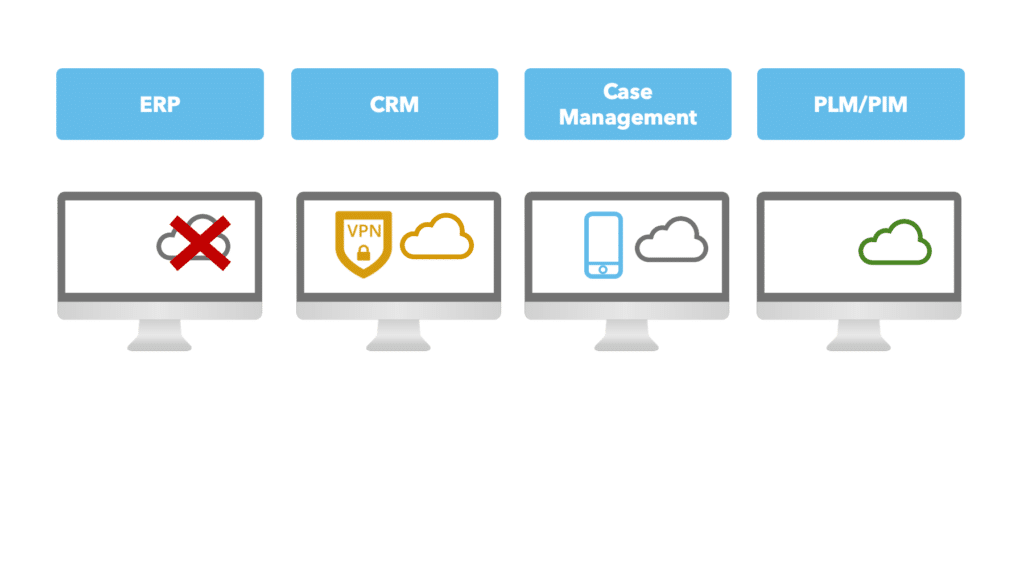

Some of the systems are new and cloud-based, others are older and locally installed. Some of the systems can be handled and adapted by the staff themselves. Other systems are dependent on the availability of external competence. There are integrations between the central business systems, especially between the ERP and CRM solutions. The CRM system is a hybrid of an older local installation that has partially been modernized into a web solution. The case management system and PIM solution were introduced in 2018 and are modern, completely pure SaaS services.

In addition to different editions, technical platforms, interfaces, and remote access capabilities, all central operating systems require a license fee per named user. Everyone that has a role in the supply chain has access to the case management system. As for the rest the company tries to keep costs for software and licenses as low as they can. This is the situation when the customer request is received. The machine manufacturer has told us what the entire delivery process and the interaction between the departments and the systems look like. There are many steps to be taken. Both steps forward and steps backward in several turns. Far too many to be described. It might be good to think about what your own optimal flow would look like. From the drawing stage to calculation, contract, partial invoicing, production, delivery, and final inspection. Who would need access to the different systems?

Covid-19 and added complexity

In the spring of 2020, the level of complexity was raised. When Covid-19 struck, it was decided that staff outside of the production and assembly stage should work from home. Many were used to working with several different applications and windows simultaneously and to automatically have access to all systems when logged in to the computer’s operating system. Soon there were bottlenecks and a drop in productivity which were solved by purchasing monitors for home offices and updates to the tools for remote access. The pandemic has shown many companies that they quickly can solve technical problems when you must. Lack of time and money is not always the real obstacle for speeding up digitalization. But not even the best of intentions will solve the most difficult part – that most of the systems used are rarely built for collaboration and interplay processes.

Which system will decide what the delivery process will look like?

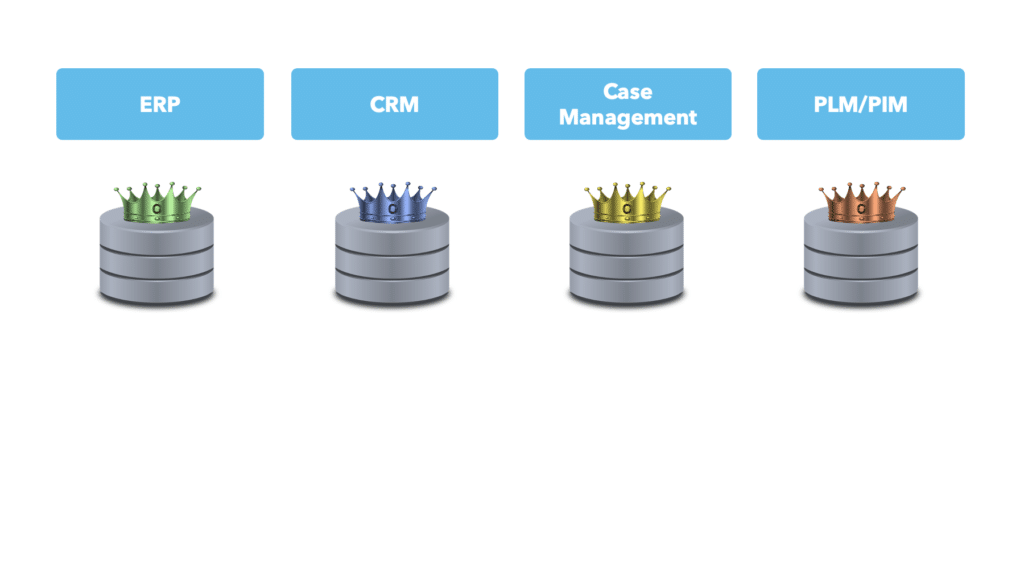

If we focus on the four central operating systems in the example, then every system would like to declare itself superior to the other systems. They all have good arguments for why and point to their main asset. Their own master data and the optimal workflows for how this master data should be used best.

ERP usually has the most modules and the most control over finances and transactions with other resources. CRM has the details of the extremely important customer relationships. The case management system is the master of coordinating who controls and supervises the projects. PIM controls the machines’ life cycles, history, drawings, and all marketing materials. Who then has the most legitimate right to rule them all?

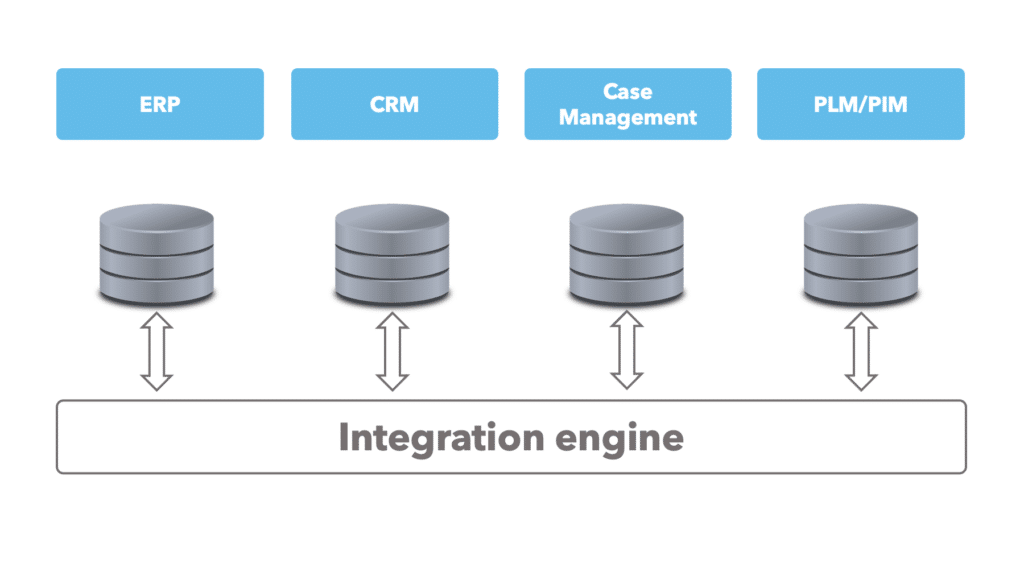

Integration engine as a digital diplomat

In this situation, a so-called integration engine can act as a digital diplomat and send appropriate messages with data between the various systems. A smart integration engine can also initiate very complex workflows completely controlled by different conditions and conditional chains.

BizTalk Server is a well-known brand. To the extent that it is sometimes incorrectly used as a collective term for various integration engines and message brokers.

With the integration engine in place, the real paradox still remains. Shared data does not mean shared processes. The systems’ individual strengths and specific business logic used to perform their primary tasks make them limited when they are supposed to lead entire process flows. Nor do they have the natural conditions to provide a good overview of several different roles. All systems have full access to each other’s data. However, their flows and tools are adapted for groups of specialists with different tasks and information needs. Thus, the problem is not only where common data should be stored and calculated. It’s also about which meeting place is most suitable for the users.

Trying to design a universal system and system support optimized for a large number of people in development, production, sales, service, and finance, etc. directly contrasts two sayings: ‘Nothing is impossible’ and ‘a compromise is a solution where no one is really satisfied’.

Turning our eye towards the rest of the world, what do we see in terms of system support?

A small consolation is the fact that most other organizations are facing a big challenge when it comes to optimizing their own processes, digitalize them, and making them a cohesive whole. We notice it ourselves. There is constant fine-tuning needed combined with greater effort and itinerant point efforts. If it’s already now difficult to synchronize your internal flows. How are we able to create solutions where all our customers, suppliers, and partners can coordinate their processes?

No two companies work exactly alike, but every company needs more and more information to be able to act and plan increasingly complex processes. Preferably in real-time and preferably in a format that can be interpreted without processing.

What will our next piece be about?

Here we have shared our view of machine manufacturers, good system support, and the aftermarket, and at the same time stated that it will be quite difficult anyway. It may not seem that encouraging but we share this information with you with the perspective that no solution is better than the problems it can reduce.

In the next article, we will also not give all answers to the questions we ask. However, we promise to focus more on what a machine manufacturer should do to reach the light in the tunnel faster and safer. Stay tuned and do not forget to sign up for our newsletter and follow us on LinkedIn.

The series of articles about innovative machine manufacturers and their place in the aftermarket so far:

- The costs to avoid in your aftermarket

- The deficient system support and the aftermarket (this one)

- IOT factory automation for increased aftermarket sales

- How your aftermarket benefits from a data-driven service book

- How to increase sales in your aftermarket with digital sellers

- Oee and how to develop your features in the right order

- (Subscribe)