ALL-IN-ONE INTERFACE FOR SMOOTH PRODUCTION

Connectitude OEE provides operators with a seamless interface where they can easily oversee and manage their workday. Here, everything needed to keep track of tasks, monitor production flow, and report any deviations or time-consuming stops is available. Thanks to our smooth integrations, maintaining an uninterrupted workflow has never been easier – operators don’t need to switch between different programs or systems, saving both time and frustration.

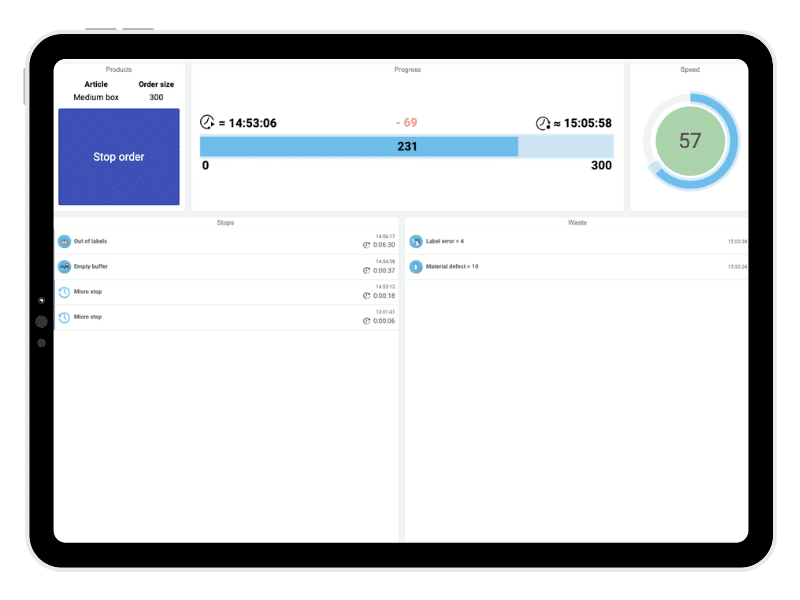

QUICK OVERVIEW

In the specially tailored interface, operators can easily select which orders are being processed. With our integrations, this information can come from your planning in ERP systems or Excel. A quick overview provides operators with information on speed, progress on current orders, and expected completion times. If the system detects a stoppage, the operator is immediately alerted and can provide information on why production has halted.

FAST AND EASY REGISTRATION IN DEMANDING ENVIRONMENTS

In production environments where every second counts, it’s crucial to be able to identify and address downtime efficiently. Connectitude OEE’s stoppage registration is designed to do just that – giving your operators the ability to quickly report stoppage causes without it becoming burdensome.